Application field

1. Uninterruptible power supply 2. Photovoltaic inverter 3. Server power 4. DC charging pile 5. New energy vehicles 6. Air conditionerPerformance Characteristics

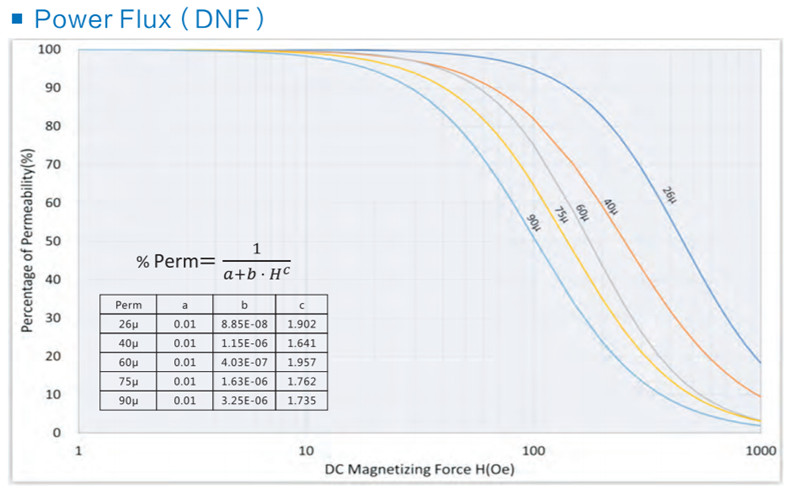

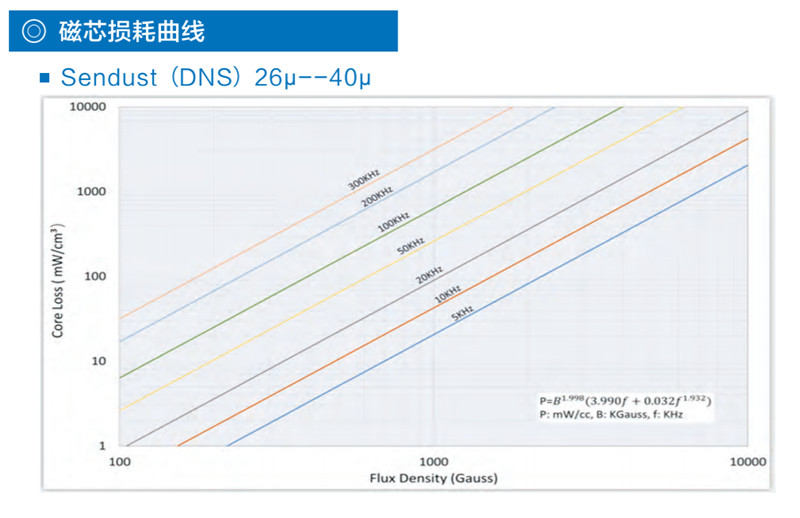

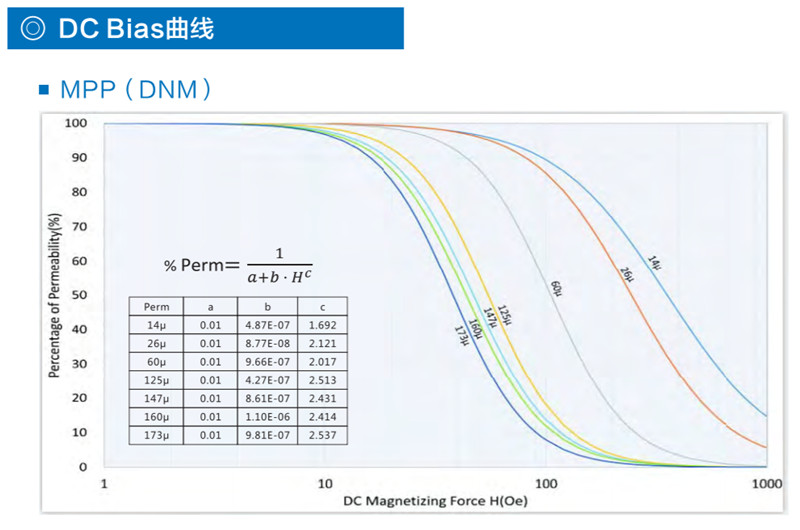

· Has a uniformly distributed air gap ·High saturation magnetic flux density (1.2T) ·Low loss · Low magnetostriction coefficient · Stable temperature and frequency characteristicsCraftsmanship

Sendust core are formed by adding a certain amount of glass forming agent to the molten metal, and rapidly quenching and casting using a narrow ceramic nozzle under high temperature melting conditions. Amorphous alloys have the similar characteristics of glass structure, which not only make them have excellent mechanical properties, physical properties and chemical properties, but more importantly, the new technology of producing amorphous alloys using this rapid quenching method is less than the cold-rolled silicon steel sheet process. 6 to 8 processes can save energy consumption by 60% to 80%, which is an energy-saving, time-saving and efficient metallurgical method. Moreover, the amorphous alloy has low coercivity and high magnetic permeability, and its core loss is significantly lower than that of oriented cold-rolled silicon steel sheet, and its no-load loss can be reduced by about 75%. Therefore, the use of amorphous alloys instead of silicon steel sheets to manufacture transformer cores is one of the main means to save energy and reduce consumption in today's power grid equipment.Parameter Curve