Parameter Curve

AC Reactor | DC Reactor | PFC boost inductor: Under 6kW (Mircolite 100µ), Over 6kW Common mode chokes | MagAmp | Differential mode chokes / SMPS output inductor Spike absorbing cores

AC Reactor | DC Reactor | PFC boost inductor: Under 6kW (Mircolite 100µ), Over 6kW Common mode chokes | MagAmp | Differential mode chokes / SMPS output inductor Spike absorbing cores Performance Characteristics

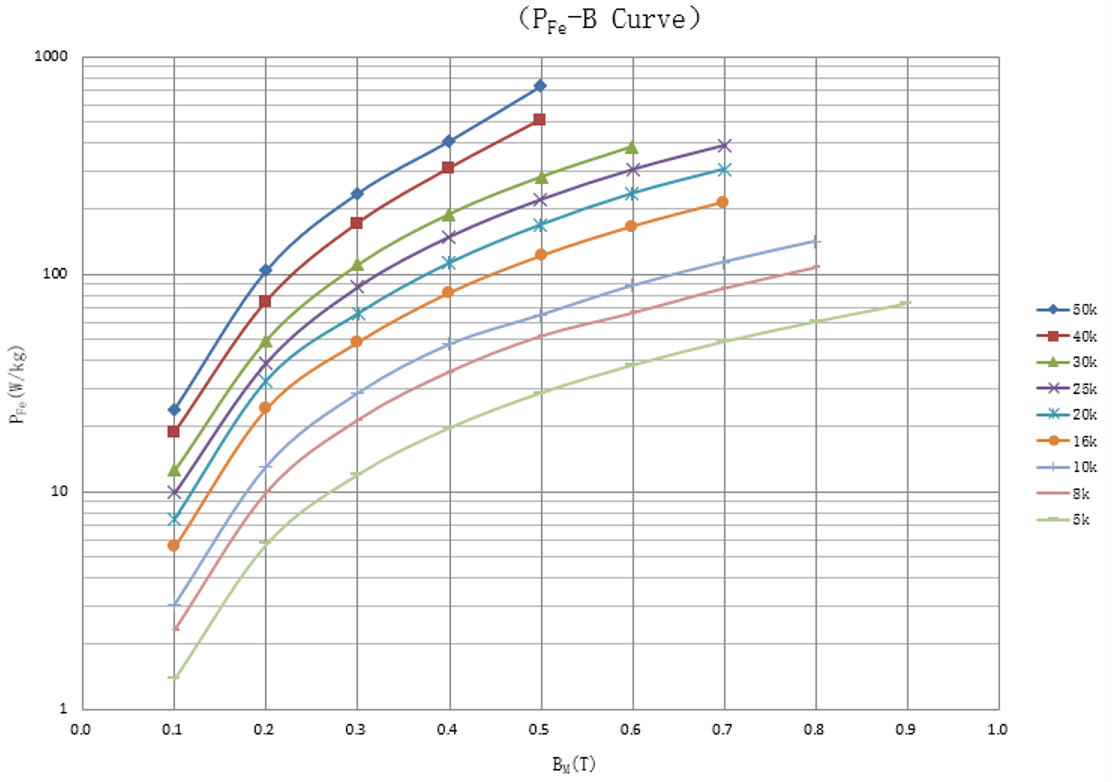

·High saturation magnetic induction intensity-reduce core volume, ·Rectangular structure - easy coil assembly Core opening - excellent resistance to DC bias saturation ·Low loss - reduce temperature rise (1/5-1/10 of silicon steel) ·Good stability—can work at -50~130℃ for a long timeTechnical advantage

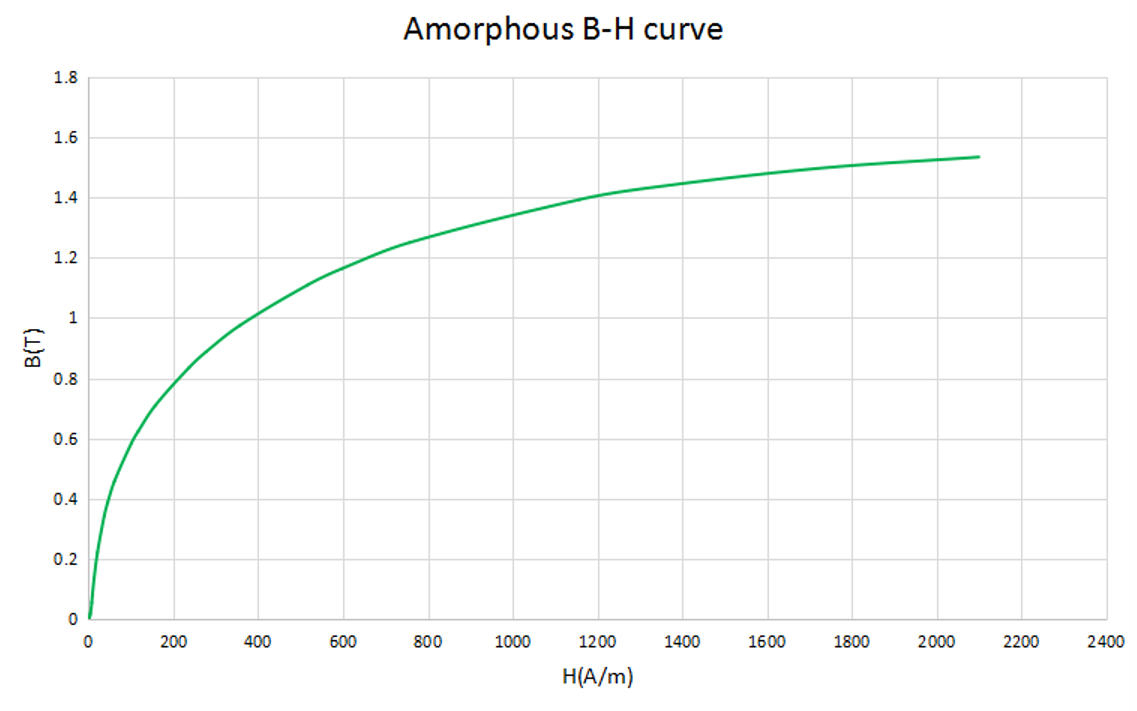

Where typical ferrite cores can only operate up to a flux saturation level (Bsat) of 0.49 Tesla, amorphous metal cores can be operated at 1.56 Tesla. Combined with operating at permeability similar to high-end ferrites and the flexibility of manufacturing large cores sizes these cores can be an ideal solution for many of these components.| NO. | Item | Unit | Reference value |

| 1 | (Bs) Saturated induction density | T | 1.5 |

| 2 | HC | (A/M) | 4 Max |

| 3 | (Tx) Curie Temperature | ℃ | 535 |

| 4 | (Tc) Curie Temperature | ℃ | 410 |

| 5 | (ρ) Density | g/ cm3 | 7.18 |

| 6 | (δ ) Resistivity | μΩ·cm | 130 |

| 7 | (k) Stacking Factor | - | >0.80 |

Craftsmanship

Amorphous alloys are formed by adding a certain amount of glass forming agent to the molten metal, and rapidly quenching and casting using a narrow ceramic nozzle under high temperature melting conditions. Amorphous alloys have the similar characteristics of glass structure, which not only make them have excellent mechanical properties, physical properties and chemical properties, but more importantly, the new technology of producing amorphous alloys using this rapid quenching method is less than the cold-rolled silicon steel sheet process. 6 to 8 processes can save energy consumption by 60% to 80%, which is an energy-saving, time-saving and efficient metallurgical method. Moreover, the amorphous alloy has low coercivity and high magnetic permeability, and its core loss is significantly lower than that of oriented cold-rolled silicon steel sheet, and its no-load loss can be reduced by about 75%. Therefore, the use of amorphous alloys instead of silicon steel sheets to manufacture transformer cores is one of the main means to save energy and reduce consumption in today's power grid equipment.