Parameter Curve

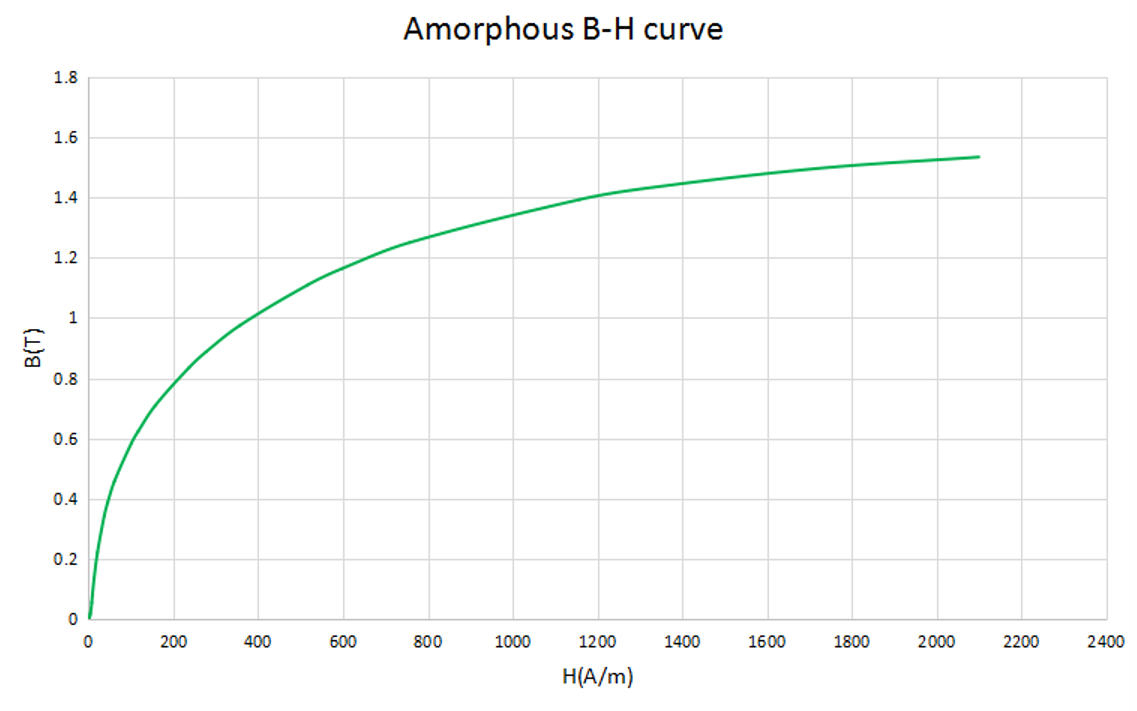

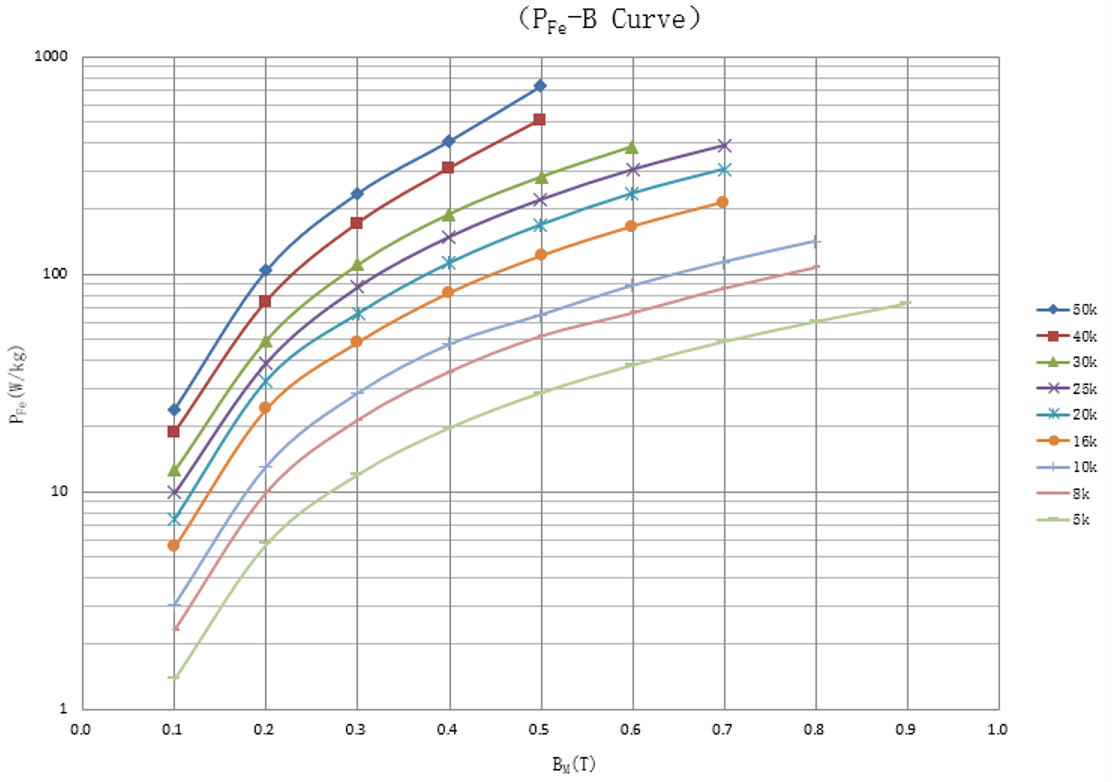

Amorphous alloy transformer is a low loss, high energy efficiency power transformer. This type of transformer uses an iron-based amorphous metal as the iron core. Since the material does not have a long-range ordered structure, its magnetization and demagnetization are easier than those of general magnetic materials. The iron loss of amorphous alloy transformers is 70-80% lower than that of traditional transformers that generally use silicon steel as the iron core. As losses are reduced, the demand for electricity generation is also reduced, with a corresponding reduction in greenhouse gas emissions such as carbon dioxide. Based on the factors of energy supply and environmental protection, amorphous alloy transformers are widely used in large developing countries such as China and India. If amorphous alloy transformers are fully used in the distribution network, it can save about 25-30TWh of power generation and reduce carbon dioxide emissions by 20-30 million tons per year. The biggest advantage of amorphous alloy iron core distribution transformer is that the no-load loss value is extremely low. Whether the no-load loss value can be finally guaranteed is the core issue to be considered in the entire design process. When arranging the product structure, in addition to considering that the amorphous alloy core itself is not affected by external force, the characteristic parameters of the amorphous alloy must be accurately and reasonably selected during the calculation. The use of amorphous alloys with outstanding magnetic permeability is used as the iron core material for the manufacture of transformers, and ultimately a very low loss value can be obtained. But it has many characteristics that must be guaranteed and considered in the design and manufacture.

Amorphous alloy transformer is a low loss, high energy efficiency power transformer. This type of transformer uses an iron-based amorphous metal as the iron core. Since the material does not have a long-range ordered structure, its magnetization and demagnetization are easier than those of general magnetic materials. The iron loss of amorphous alloy transformers is 70-80% lower than that of traditional transformers that generally use silicon steel as the iron core. As losses are reduced, the demand for electricity generation is also reduced, with a corresponding reduction in greenhouse gas emissions such as carbon dioxide. Based on the factors of energy supply and environmental protection, amorphous alloy transformers are widely used in large developing countries such as China and India. If amorphous alloy transformers are fully used in the distribution network, it can save about 25-30TWh of power generation and reduce carbon dioxide emissions by 20-30 million tons per year. The biggest advantage of amorphous alloy iron core distribution transformer is that the no-load loss value is extremely low. Whether the no-load loss value can be finally guaranteed is the core issue to be considered in the entire design process. When arranging the product structure, in addition to considering that the amorphous alloy core itself is not affected by external force, the characteristic parameters of the amorphous alloy must be accurately and reasonably selected during the calculation. The use of amorphous alloys with outstanding magnetic permeability is used as the iron core material for the manufacture of transformers, and ultimately a very low loss value can be obtained. But it has many characteristics that must be guaranteed and considered in the design and manufacture. | NO. | Item | Unit | Reference value |

| 1 | (Bs) Saturated induction density | T | 1.5 |

| 2 | HC | (A/M) | 4 Max |

| 3 | (Tx) Curie Temperature | ℃ | 535 |

| 4 | (Tc) Curie Temperature | ℃ | 410 |

| 5 | (ρ) Density | g/ cm3 | 7.18 |

| 6 | (δ ) Resistivity | μΩ·cm | 130 |

| 7 | (k) Stacking Factor | - | >0.80 |