Amorphous iron oxide refers to iron oxide that lacks a well-defined structure, leading to a range of unique properties. In terms of applications, it is widely used in biomedical imaging, water treatment, magnetic storage, and electronic devices, to name a few. The traditional methods used to synthesize amorphous iron oxide are often time-consuming, expensive, and may require hazardous chemicals.

With this in mind, researchers from the Department of Chemistry, Bar-Ilan University in Israel, and the Oak Ridge National Laboratory in the United States, have developed a new method for preparing amorphous iron oxide using microwave heating. Their research was published in the Journal of Materials Research.

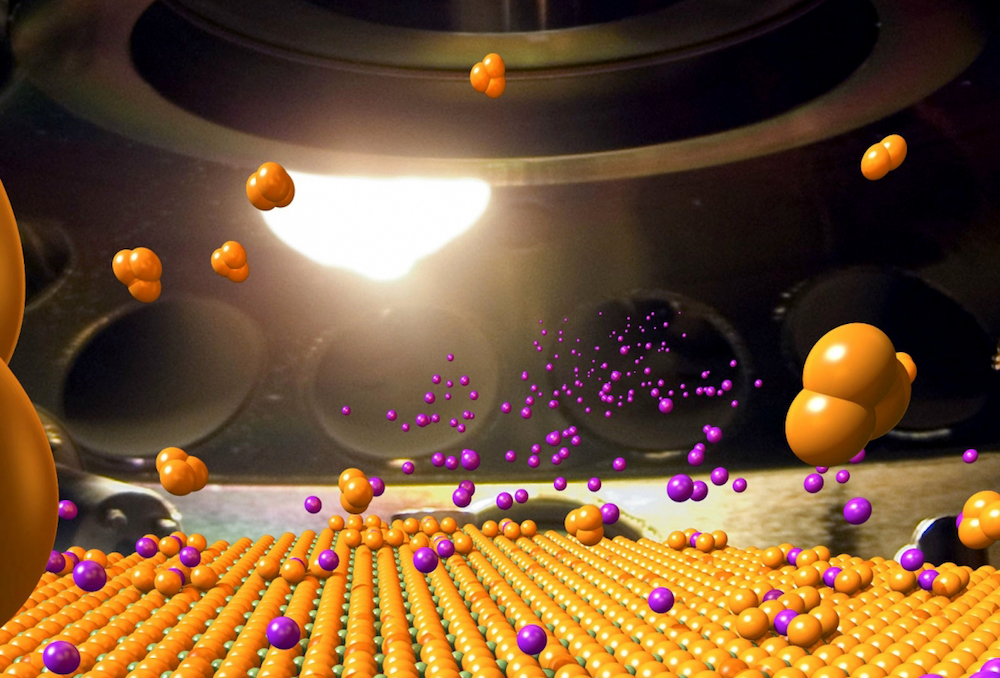

The process of synthesizing amorphous iron oxide using microwave heating involves the application of a microwave field to a solution containing iron precursors. The solution is then treated until the temperature reaches 240°C for 45 minutes. This results in the heating of the solution, causing rapid and uniform nucleation of iron oxide nanoparticles that have amorphous structures.

One advantage of using microwave heating technology to prepare amorphous iron oxide is that it allows for the quick and efficient synthesis of large quantities of nanoparticles. The researchers also discovered that the quality of the synthesized iron oxide particles improved significantly compared to traditional synthesis methods.

The synthesized nanoparticles were analyzed by various techniques, including X-ray diffraction (XRD), transmission electron microscopy (TEM), and Mössbauer spectroscopy. These analyses revealed that the nanoparticles were nearly spherical in shape, with a narrow particle size distribution, and exhibited excellent magnetic properties.

The amorphous iron oxide nanoparticles synthesized through microwave heating could provide significant benefits to various areas of science and technology. The use of iron oxide nanoparticles in biomedicine, for instance, could enable the delivery of drugs to specific regions of the body through magnetically guided targeting. Magnetic hyperthermia and imaging are also other potential uses for these nanoparticles.

In conclusion, the synthesis of amorphous iron oxide using microwave heating is a promising approach in materials science. It offers a simple, efficient, and cost-effective method of producing high-purity iron oxide nanoparticles with consistent size and shape. The potential applications for amorphous iron oxide nanoparticles are vast and varied, making this technology an important and exciting development in scientific research.

Keywords: Amorphous Core, Iron Core, Microwave Heating, Nanoparticles, Polymerization, Synthesis.